Direct-to-Film (DTF) printing is a modern method of printing and is being increasingly adopted by the textile and apparel industry. Offering unparalleled flexibility in order quantities, durable prints, and satisfactory quality, DTF is a top choice for companies looking to print on demand or young brands looking to keep a large design roster while maintaining just-in-time inventory. At Plakads Apparel, our commitment to excellence ensures every DTF print is both durable and aesthetically pleasing. Here are some pivotal guidelines to ensure the best DTF print results:

Properly Size Your Files

Why is it important?

Your print's accuracy and vibrancy are intrinsically tied to the quality of your image file. A high-resolution image ensures a sharp and detailed print, while a low-res one can lead to distortions, such as white line edges – a common pitfall in DTF Printing.

- DPI Standards: Target images with a DPI range of 300-450. This reflects the print's detail density. Avoid exceeding 450 DPI; DTF printers might compress such files, leading to unexpected outcomes.

- Image vs. Print Size: If your desired print size is 10 x 11 inches on a t-shirt, ensure your design file is of similar dimensions. Expanding a smaller image stretches its pixels, causing graininess or blurriness.

Avoid Transparencies and Translucencies

Why is it important?

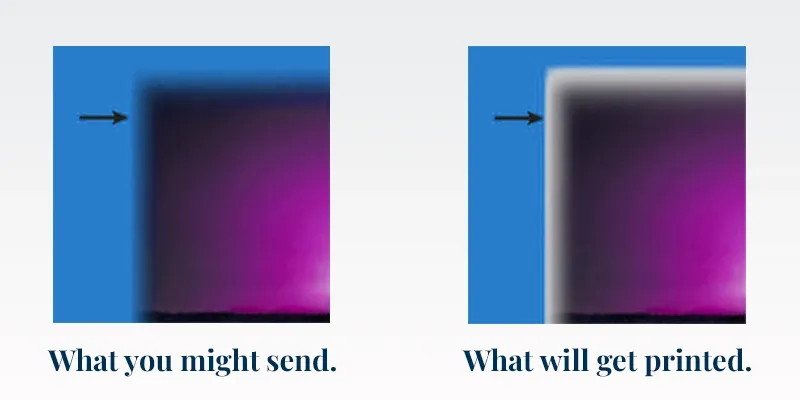

DTF printers can't process transparencies or translucencies. These areas default to white, potentially compromising your design. Any transparency will result in the white showing, as shown in the example image below.

- DTF Process: These printers apply ink to a film, which is then transferred to fabric. They can't bypass transparent regions, which, thus, appear as white.

- Design Verification: Use software like Adobe Photoshop to view designs layer-by-layer, helping spot and eliminate transparent regions.

Avoid Elements That Are Too Small

Why is it important?

Tiny design elements might not secure well to the fabric, risking rapid wear and tear. Plus, they may lose clarity when printed.

- Size Guidelines: Ensure all design elements are larger than 0.5 cm for durability and visibility.

- Design Clarity: Smaller elements can lose definition when printed, affecting the overall aesthetic.

Colour Profiles and Conversion

Why is it important?

The CMYK colour model replicates how printers function, ensuring on-screen colours match printed ones.

- CMYK Profiles: Adopt standard profiles like U.S. Web Coated (SWOP) v2 or Coated FOGRA39 for consistent results.

- RGB to CMYK: Designs in RGB are converted to CMYK during printing, which can alter colours. Start with CMYK designs for accuracy.

Fusing Practicalities

Why is it important?

DTF Printing is only half the journey, the print now needs to be fused to the fabric to create the end products and that stage also comes with its factors. Ensure that you communicate the position of the print, clearly along with the size of the motif alongside the design. Improper fusing will lead to low durability of the DTF Prints.

- Fabric Texture: DTF excels on smooth, plain fabrics. Textured fabrics like pique or those with raised patterns can hinder proper ink transfer, affecting print quality.

- Heat Distribution: Avoid seams, stitchings, or edges. These can disrupt even heat distribution, which is crucial for DTF printing. At Plakads Apparel, we often print on finished products, so it's essential to choose areas with no obstructions for the best results. This however can be avoided by printing on cut pieces but the same is not possible on small order quantities.

Additional Tips for Optimal DTF Printing:

- Care: Educate your customers on care guidelines. Direct heat, like ironing directly on the print, can damage it. Also, provide clear washing directives.

- File Integrity: Encoding files ensures your design remains unchanged and protected from unintentional modifications. It maintains the design's integrity from approval to printing.

- Print Positioning: While DTF can be applied to various parts of apparel, avoid areas like hems, seams, or folds. The uneven surface can cause inconsistencies in print transfer.

Direct-to-Film printing has ushered in a new era of apparel customization. With Plakads Apparel at the helm, armed with the latest machinery and best practices, your prints are not just another design but a reflection of craftsmanship and quality. Adherence to these guidelines ensures every DTF product you receive is nothing short of exceptional.