At Plakads Apparel, we take great pride in being a leading job work stitching factory and contract manufacturing apparel unit in India. Our cutting and stitching process is a vital part of our commitment to providing high-quality apparel items to our clients.

We use precisely crafted performas to ensure that every garment is sized correctly, and our cutting process is carefully done in-house under strict control to minimize wastage and ensure quality. Our experienced craftsmen oversee every step of the process, ensuring that the garments are cut precisely and accurately.

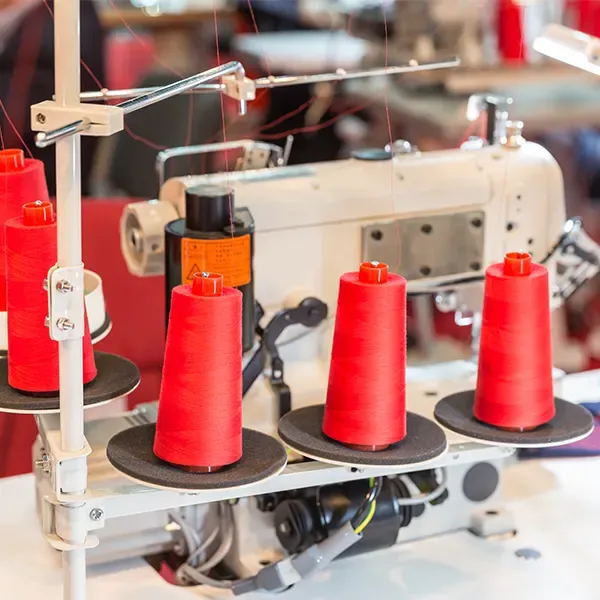

For stitching, we use state-of-the-art, latest Japanese machinery that ensures consistent and high-quality stitching. Our veteran craftspeople are skilled in using this machinery, ensuring that every garment is stitched with care and precision.

With our wide range of fabrics, we have the ability to craft any apparel items, from readymade garments to made-to-order customized products. Our in-house designers work closely with our clients to ensure that their vision is brought to life, and we use state-of-the-art software that leverages AI to ensure further on-time production and efficiencies.

At Plakads Apparel, we understand the importance of meeting the specific needs and requirements of our clients. As a job work stitching factory and contract manufacturing apparel unit, we offer customized solutions that meet the exact specifications of our clients. We work closely with our clients to ensure that we deliver high-quality products on time and within budget.

Our cutting and stitching process is a crucial part of our commitment to delivering quality products that meet the highest standards. As a job work stitching factory and contract manufacturing apparel unit, we understand the importance of quality and consistency in every garment we produce. Our process ensures that every garment is crafted to the specific needs and requirements of our clients, ensuring their satisfaction and loyalty

With a large number of machines in our possession to run parallel productions, along with the ability to quickly scale labor and machines, we provide fast stitching and cutting. Multiple cutting tables and AI leveraged production control software ensure minimal wastage and speeds. We have a standing capacity to produce 1000 garments daily, with the ability to expand this 3-fold.

Yes, for regular customers with established relations, we can produce even a single piece provided material availability. Contact us for your custom apparel needs, our in-house design team will work with you to create a size chart and performa. We can also help guide you in making custom apparel items.

Yes, you can purchase sample pieces from our wide range of wholesale products. Check the ready-made section for details. You can also visit our office to see samples.

We have strict quality control with checks at multiple levels, not just the final stage, ensuring that 90% of defective cuts don't even get stitched. This also reduces wastage further. We also carefully store the fabric waste and work with partner units to recycle and reuse them. We are committed to environmentally sustainable practices and are continuously exploring new initiatives to reduce our carbon footprint.